Pipes & Tubes

Master Metal offers a diverse range of pipes and tubes engineered for reliability and performance in demanding environments. We specialize in high-quality Stainless Steel Seamless Pipes, known for their exceptional strength, corrosion resistance, and smooth finish. Our pipes are manufactured to meet international standards such as ASTM, ASME, and DIN. They are widely used in industries like oil & gas, petrochemicals, construction, and power generation. With a commitment to quality and precision, Master Metal ensures dependable solutions for every application.

ASTM A106 Grade B Carbon Steel Pipes Specification

| Specification | Description |

|---|---|

| Standard | ASTM A106 |

| Grade | Grade B |

| Type | Seamless and Welded |

| Size Range | 1/2" - 36" |

| Wall Thickness | SCH 40, SCH 80, SCH 160, XXS |

| Length | Single Random, Double Random, Cut Length |

| Ends | Plain End, Beveled End, Threaded |

| Surface Coating | Black or Galvanized |

Chemical Composition of ASTM A106 Grade B Carbon Steel Pipes

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.30% max |

| Manganese (Mn) | 0.29–1.06% |

| Phosphorus (P) | 0.035% max |

| Sulfur (S) | 0.035% max |

| Silicon (Si) | 0.10% min |

| Chromium (Cr) | 0.40% max |

| Copper (Cu) | 0.40% max |

| Nickel (Ni) | 0.40% max |

| Molybdenum (Mo) | 0.15% max |

Specification of Stainless Steel 304/304L/304H Seamless Welded Pipes And Tubes

| Stainless Steel Pipe Specification | ASTM A312, A358 / ASME SA312, SA358 |

|---|---|

| SS Tube Specification | ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554 |

| Pipe Size | 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes |

| Tube Size | 1/2" OD to 8" OD |

| Thickness Range | 0.3mm – 50mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Type | Seamless / ERW / Welded / Fabricated Pipes |

| Form | Round, Square, Rectangular, Oval, Hydraulic etc. |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Threaded |

| End Protection | Plastic Caps |

| Outside Finish | 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer requirements |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Inspection, Test Reports |

Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customer Requests |

| Specials | Sizes and Specifications other than above can be manufactured on request |

Exporters of Carbon Steel Pipe & SS Pipes and Tube

| Saudi Arabia | Qatar | Canada | Bangladesh |

| Oman | UAE | Venezuela | Turkey |

| Kuwait | Africa | United Kingdom | Singapore |

| Netherlands | China | Malaysia | Sri Lanka |

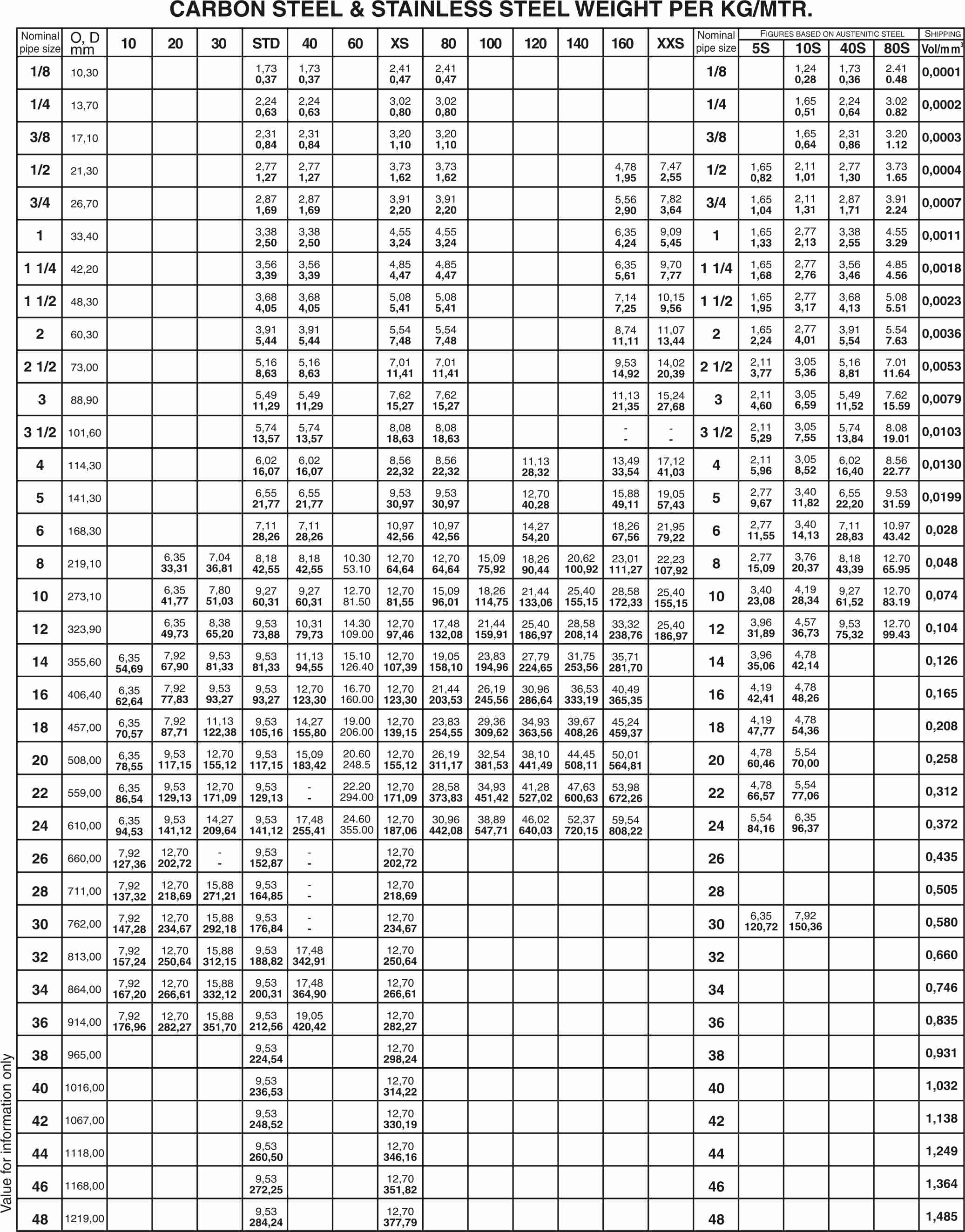

Weight Chart For Pipes

Standards and Certification

| Property | Details |

|---|---|

| Material | Carbon Steel (commonly ASTM A106, ASTM A53, API 5L) |

| Grades | ASTM A106 Grade A, B, C ASTM A53 Grade A, B API 5L B, X42, X46, X52, X56, X60 |

| Composition | Carbon (0.05% to 2.0%) Manganese (up to 1.65%) Phosphorus and Sulfur (up to 0.05%) |

| Yield Strength | 250-540 MPa (depending on grade and size) |

| Tensile Strength | 400-700 MPa (depending on grade and size) |

| Elongation | 20-30% (depending on grade and wall thickness) |

| Hardness | 120-170 HB (depending on carbon content and heat treatment) |

| Thickness | 1.65 mm to 40 mm (depends on pipe size and grade) |

| Diameter | 1/8 inch to 80 inches (varies by grade and schedule) |

| Wall Thickness Classes | Schedule 40, 80, 160 Schedule XS (Extra Strong) Schedule XXS (Double Extra Strong) |

| Temperature Range | Up to 400°C (for normal carbon steel) Higher limits possible with alloyed grades (up to 600°C) |

| Applications | Oil and gas transmission Chemical processing Water transport Heat exchangers |

| Corrosion Resistance | Moderate; requires coating or corrosion inhibitors for harsh environments |

| Weldability | Good weldability for most grades, with preheating in higher carbon grades for thicker sections |

| Bending Radius | Minimum 3 times pipe diameter for cold bending (varies by material grade) |