Stainless Steel Sheet

| Standard | Product Form |

|---|---|

| ASTM B265 (Gr2) | Sheet, Strip, and Plate |

| ASTM B338 | Tube, Seamless and Welded |

| ASTM B348 (Gr2) | Bars and Billets |

| ASTM B861 | Seamless Pipe |

| ASTM B863 | Wire |

| ASTM F67 (Gr2) | Unalloyed Titanium for Surgical Implants |

Stainless Steel Sheet Specification

| Stainless Steel Sheets and Plates Specifications | |

|---|---|

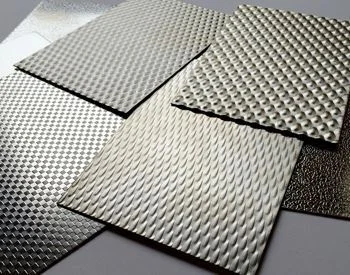

| Grades Available | 304, 304L, 316, 316L, 321, 310, 310S, 904L, 17-4PH, and more as per customer requirements |

| Thickness Range | From 0.3 mm to 100 mm (custom thicknesses available) |

| Width | Up to 2500 mm |

| Length | Up to 6000 mm, or custom-cut based on requirements |

| Finish Options |

|

| Mechanical Properties |

|

| Corrosion Resistance | Excellent resistance to rust, stains, and corrosion, ideal for harsh environments |

| Standards & Certifications |

|

| Applications |

|

Stainless Steel Sheet Thickness

| Thickness in. (mm) | Width 36" (914.4mm) | Width 48" (1,219mm) |

|---|---|---|

| 0.017–0.030 (0.43–0.76) | 0.0015 (0.038) | 0.002 (0.051) |

| 0.031–0.041 (0.79–1.04) | 0.002 (0.051) | 0.003 (0.076) |

| 0.042–0.059 (1.1–1.5) | 0.003 (0.076) | 0.004 (0.10) |

| 0.060–0.073 (1.5–1.9) | 0.003 (0.076) | 0.0045 (0.11) |

| 0.074–0.084 (1.9–2.1) | 0.004 (0.10) | 0.0055 (0.14) |

| 0.085–0.099 (2.2–2.5) | 0.004 (0.10) | 0.006 (0.15) |

| 0.100–0.115 (2.5–2.9) | 0.005 (0.13) | 0.007 (0.18) |

| 0.116–0.131 (2.9–3.3) | 0.005 (0.13) | 0.0075 (0.19) |

| 0.132–0.146 (3.4–3.7) | 0.006 (0.15) | 0.009 (0.23) |

| 0.147–0.187 (3.7–4.7) | 0.007 (0.18) | 0.0105 (0.20) |

SS Sheet Weight Chart

| Thickness in mm | Size in mm (2000 x 1000) | Size in mm (2500 x 1250) | Size in mm (3000 x 1500) | Weight kg/m² |

|---|---|---|---|---|

| 0.18 | 2.88 | - | - | 1.44 |

| 0.20 | 3.20 | - | - | 1.60 |

| 0.22 | 3.52 | - | - | 1.76 |

| 0.24 | 3.84 | - | - | 1.92 |

| 0.27 | 4.32 | - | - | 2.16 |

| 0.28 | 4.48 | - | - | 2.24 |

| 0.32 | 5.12 | - | - | 2.56 |

| 0.38 | 6.08 | - | - | 3.04 |

| 0.44 | 7.04 | 11.00 | - | 3.52 |

| 0.50 | 8.00 | 12.50 | - | 4.00 |

| 0.56 | 8.96 | 14.00 | - | 4.48 |

| 0.63 | 10.08 | 15.75 | - | 5.04 |

| 0.75 | 12.00 | 18.75 | - | 6.00 |

| 0.88 | 14.08 | 22.00 | - | 7.04 |

| 1.00 | 16.00 | 25.00 | 36.00 | 8.00 |

| 1.13 | 18.08 | 28.25 | 40.00 | 9.04 |

| 1.25 | 20.00 | 31.25 | 45.00 | 10.00 |

| 1.38 | 22.03 | 34.50 | 50.00 | 12.00 |

| 1.50 | 24.00 | 37.50 | 54.00 | 12.00 |

| 1.75 | 28.00 | 43.75 | 63.00 | 14.00 |

| 2.00 | 32.00 | 50.00 | 72.00 | 16.00 |

| 2.25 | 36.00 | 56.25 | 81.00 | 18.00 |

| 2.50 | 40.00 | 62.50 | 90.00 | 20.00 |

| 2.75 | 44.00 | 68.75 | 99.00 | 22.00 |

| 3.00 | 48.00 | 75.00 | 108.00 | 24.00 |

| 3.25 | 52.00 | 81.25 | 117.00 | 26.00 |

| 3.50 | 56.00 | 87.50 | 126.00 | 28.00 |

| 3.75 | 60.00 | 93.75 | 135.00 | 30.00 |

| 4.00 | 64.00 | 100.00 | 144.00 | 32.00 |

| 4.25 | 68.00 | 106.25 | 153.00 | 34.00 |

| 4.50 | 72.00 | 112.50 | 162.00 | 36.00 |

| 5.00 | 80.00 | 125.00 | 180.00 | 40.00 |

| 5.50 | 88.00 | 137.50 | 198.00 | 44.00 |

| 6.00 | 96.00 | 150.00 | 216.00 | 48.00 |

| 6.50 | 104.00 | 162.50 | 234.00 | 52.00 |

| 7.00 | 112.00 | 175.00 | 252.00 | 56.00 |

| 7.50 | 120.00 | 187.50 | 270.00 | 60.00 |

| 8.00 | 128.00 | 200.00 | 288.00 | 64.00 |

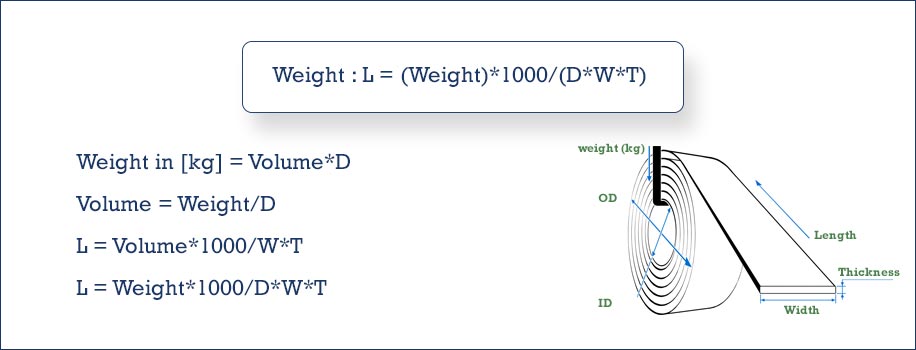

316 SS coil size chart

| Type | Thickness (mm) | Width (mm) | Surface Finish | Inner Diameter (mm) |

|---|---|---|---|---|

| SS Hot Rolled Coils | 2.5 to 10.0 | 610 to 2000 | 2B, 2D, No.4, BA, No.5, No.3, SB, HL | 610 +0/-5 |

| SS Cold Rolled Coils | 0.3 to 3.0 | 610 to 1524 | – | 610 or 508 +0/-5 |

| SS Coils | 0.4 to 3.0 | 130 | 2D, 2B | – |

410 stainless steel coil chemical composition

| Grade | Ni | C | Cr | P | Mn | S | Mo | Si | Cu |

|---|---|---|---|---|---|---|---|---|---|

| 304L | 8.00 - 10.00 | ≤0.030 | 18.00 - 20.00 | ≤0.035 | ≤2.00 | ≤0.030 | – | ≤1.00 | – |

| 304 | 8.00 - 10.00 | ≤0.07 | 17.00 - 19.00 | ≤0.035 | ≤2.00 | ≤0.030 | – | ≤1.00 | – |

| 316L | 12.00 - 15.00 | ≤0.030 | 16.00 - 18.00 | ≤0.035 | ≤2.00 | ≤0.030 | 2.00 - 3.00 | ≤1.00 | – |

| 316 | 10.00 - 14.00 | ≤0.08 | 16.00 - 18.50 | ≤0.035 | ≤2.00 | ≤0.030 | 2.00 - 3.00 | ≤1.00 | – |

316l SS coil mechanical composition

| Grade | Density | Melting Point | Tensile Strength | Elongation | Yield Strength (0.2% Offset) |

|---|---|---|---|---|---|

| SS Coil | 8.0 g/cm³ | 1399 °C (2550 °F) | Psi – 75,000 , MPa – 515 | 35 % | Psi – 30,000 , MPa – 205 |